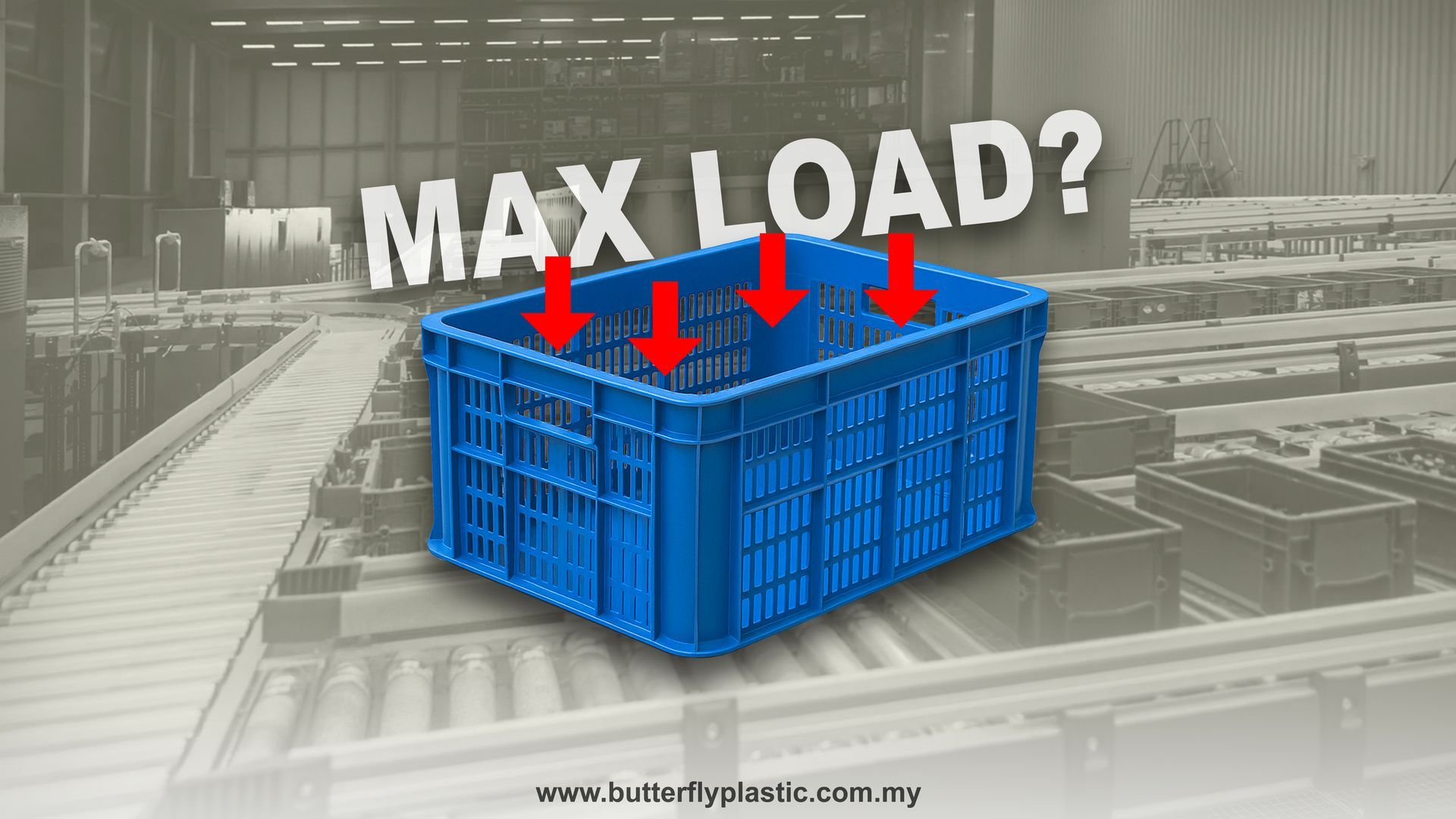

What Determines the Maximum Load of a Plastic Crate?

Understanding the Maximum Load of a Plastic Crate

One of the most common questions we receive is: “What is the maximum load this crate can carry?”

While it sounds like there should be one fixed number, the reality is that the maximum load of a plastic crate depends on several factors — from the type of goods you store to how you stack and handle the crate. In this article, we’ll explain why crate load capacity isn’t a one-size-fits-all answer and what you should consider before loading your crate.

1. Solid Items vs. Discrete Items

- The type of goods you put in a crate makes a big difference. Solid items, such as a block of metal or a solid box, naturally hold their shape. Even without a crate, they stay flat and stable. When placed inside a crate, the weight is spread evenly across the base, meaning the bottom of the crate is less likely to bend. This allows the crate to handle heavier loads.

- Discrete items, such as bottles, loose parts, or produce, behave differently. These items shift around and create pressure not only on the bottom but also on the sides of the crate. As a result, the crate’s structure has to handle extra stress from different directions, which usually means a lower safe load limit compared to solid goods.

2. Full Load vs. Half Load Stacking

- The amount of goods inside the crate affects how much load it can handle when stacked. With a full load, the first crate is completely filled, so when a second crate is placed on top, its weight is supported not just by the crate walls but also by the goods inside. This provides stronger overall support and allows for a higher maximum load.

- With a half load, the first crate is only partially filled, leaving empty space inside. In this case, the second crate’s weight is supported mainly by the crate walls and rim, which generally results in a lower maximum load compared to a full load.

3. Surface Type Matters

- The surface on which your crate rests is another important factor. On a flat, solid surface like concrete, the entire base of the crate is supported evenly, allowing it to carry more weight safely. On uneven surfaces, or when placed on rails or limited contact points, the crate’s bottom experiences more stress in certain spots, which lowers its load capacity.

4. Temperature and Environment

- Environmental conditions affect plastic strength. In cold environments, plastic can become brittle, making it more prone to cracking under heavy weight. In hot environments, it can become more flexible, which may cause deformation when heavily loaded. Always consider the storage or transport conditions when estimating safe load capacity.

5. Handling Method

- The way you handle your crate plays a big role. A crate holding a heavy load might be perfectly safe when stationary, but if you lift it unevenly, drop it, or move it on a forklift with forks spaced incorrectly, it can fail even below its “maximum” capacity.

Conclusion

The maximum load of a crate is not just a number — it’s the result of multiple factors working together. By understanding your goods, stacking method, surface type, material, temperature, and handling method, you can choose the right crate and load it safely for your needs.

We design and manufacture crates with strength, durability, and safety in mind. If you’re unsure which crate suits your application, our team can recommend the best option for your load requirements.